Packaging technology that has exceeded borders in 20 years: Roboplas

In this edition, we sat down with Onur Oral, General Manager of Roboplas, a company that has been delivering innovative solutions to the packaging industry for two decades. We explored Roboplas journey from its founding to its current global presence, including its cutting-edge technologies such as IML in-mold labeling robots, product pick-up robots, and Robovision camera-based quality control systems.

In this edition, we sat down with Onur Oral, General Manager of Roboplas, a company that has been delivering innovative solutions to the packaging industry for two decades. We explored Roboplas journey from its founding to its current global presence, including its cutting-edge technologies such as IML in-mold labeling robots, product pick-up robots, and Robovision camera-based quality control systems.

Roboplas has completed its 20-year journey in the industry. Could you share with us the key milestones of this journey and where the company stands today?

Roboplas was founded 20 years ago by three partners—Zafer Kirik, Aydın Özkaymaz, and Onur Oral— with a vision to shape the future of packaging. Today, the company has far surpassed that goal, becoming a global brand with exports to 45 countries and over 950 active robotic systems worldwide.

Roboplas made history as the first Turkish company to participate in international trade fairs with domestically produced IML robots. Over the years, strategic investments have expanded its visibility and vision. In 2017, Roboter was established, followed by Roboplas North America Inc. in Canada in 2019. The launch of the Robovision brand in 2014 marked a new chapter, introducing proprietary camera-based quality control systems to the market.

In 2024, Roboplas opened its Robot Center factory in Silivri Çanta, initiating production and unveiling a new showroom. The facility features the Arburg Allrounder 630H-2300-800 HP machine, acquired through a long-standing partnership with Arburg. A new collaboration with SahaDX enabled the integration of Irayple 2D and 3D cameras, Zebra barcode readers, and Matrox software into Roboplas systems—laying the groundwork for expanded domestic and international market offerings.

Throughout this journey, Roboplas has continuously evolved across engineering, manufacturing, sales, and technical support. Today, it stands as a global leader in IML robotics and rigid packaging automation.

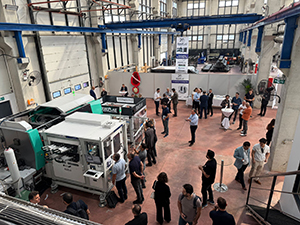

To mark its 20th anniversary, Roboplas hosted the Packaging Technology Day—an event that showcased the future of packaging through collaboration. Industry leaders such as Arburg, Erkoç, I- Tech, MCC Label, Moretto, and SahaDX joined forces to demonstrate live applications and innovations.

How will your 20th anniversary influence Roboplas’s vision for the future?

According to Onur Oral, the 20th anniversary was not a milestone, but a launchpad. The event clarified Roboplas’s future vision: delivering more integrated global solutions, accelerating digitalization, and building strong partnerships. The company now designs complete production ecosystems, with a focus on sustainability, AI-powered systems, and digital infrastructure integration.

Could you tell us about the Packaging Technology Day event? What key messages did you aim to convey to the participants?

Packaging Technology Day, held at the new Silivri facility, brought together Türkiye’s leading IML packaging producers. Attendees witnessed the live production and boxing of a high-speed 4-cavity cream cheese container using IML robotics, along with demonstrations of MCC Label’s labeling technology, Erkoç’s mold engineering, I-Tech’s cooling systems, and Robovision and SahaDX’s quality control solutions. Moretto, Schneider Electric, and Festo also contributed to the event.

The message was clear: “The future of packaging technology is shaped through collaboration.” Roboplas proved itself not only as a manufacturer, but as a driving force behind the industry’s technological evolution.

What are the contributions of Roboplas’s IML in-mold labeling robots to the industry?

What are the contributions of Roboplas’s IML in-mold labeling robots to the industry?

Roboplas’s IML robots and Robovision systems offer high-speed, flexible, and globally scalable automation solutions that enhance production efficiency, quality control, and customer satisfaction across the packaging industry.

Contributions of Roboplas IML In-Mold Labeling Robots to the Industry

When designing our IML robots, we begin by understanding the specific needs of each customer. Based on this input, we create a customized robot design. Our priorities during the design process include compact footprint, high production efficiency, comprehensive safety measures, high-speed operation, and continuous usability.

Key contributions of our IML robots include:

• High-speed production and efficiency

• Consistent quality and standardization

• Flexibility and design freedom for different molds

• Compliance with global market standards

• Support for sustainability

• 24/7 technical service and support

• Established technical support and spare parts availability in North America and Europe

What advantages do your camera-based quality control systems offer?

Thanks to our Robovision brand and our partnership with SahaDX, which provides hardware and software support, we perform comprehensive quality control on the production line and record the data statistically. Robovision is used in many countries and can be integrated not only into our own robots but also into other brands and applications. We aim to establish Robovision as a global brand in the near future.

Our system detects issues such as label misplacement, presence/absence of labels, label accuracy, print defects, burrs, black spots, and missing prints, instantly removing defective products. This transforms quality control from a standalone process into an integral part of production—resulting in lower waste rates and higher customer satisfaction.

We use high-resolution cameras, custom computer-supported software, and special lighting. Technologies include Irayple, Matrox Software, Zebra Readers, Allied Vision, and Ricoh.

What innovations do your take-out robots offer?

What innovations do your take-out robots offer?

Developed jointly with Roboter, our product take-out robots can reduce cycle times to as low as 0.6 seconds, transferring products to conveyors or boxing them upon request. The chassis and moving modules are engineered to withstand these high speeds.

Thanks to servo motor technology and modular architecture, our robots adapt easily to different product types. Remote access allows for software updates, significantly reducing maintenance costs. These robots have become a critical solution for optimizing operations and boosting efficiency on production lines.

What core technology and engineering approach sets Roboplas apart from its competitors?

Since our founding, we’ve continuously invested in facilities, technology, R&D, software, hardware, and personnel. We collaborate with world-renowned companies like Arburg on joint projects.

Our references include both major global corporations and small businesses. We hold numerous patents and utility models, and we run projects with TÜBİTAK and KOSGEB. With 85% of our production exported, our main competitors are European manufacturers—highlighting our robust technological and engineering foundation.

What does your new Silivri facility represent as an investment for your company?

Our Silivri facility marks a new phase for Roboplas. Named the Roboplas Robot Center, it features a 2300 m² single-story production area with welding, machining, assembly lines, and storage.

With our Arburg injection machine and robot in the showroom, we offer live demonstrations and allow customers to test their robots with injection machines. We also host events like Packaging Technology Day and conduct Factory Acceptance Tests (FAT) tailored to customer needs.

This facility not only boosts our production capacity but also strengthens customer engagement and showcases our technology in real-world settings.

What are your customer relations and sales strategies?

What are your customer relations and sales strategies?

Customer relationships have been a priority since day one. We value face-to-face visits and actively participate in domestic and international trade fairs. These interactions help us understand customer needs and build long-term success.

I’d like to thank our sales team and all employees. Their relationships go beyond marketing—they’re built on collaboration. The synergy between our sales, technical support, service, and design teams ensures continuity and success.

After-sales service and technical support are also crucial. Our teams in Canada and Türkiye provide 24/7 support. We sell directly from Istanbul and support North and South American clients via our Toronto office. Events like Packaging Technology Day and conferences allow us to engage directly with companies and better analyze their needs.

What would be your final message to the readers of Plastics & Packaging Technology Magazine?

The packaging industry no longer grows in isolation—it thrives through collaboration. At Roboplas, we’re at the heart of this transformation. Together with our project partners and strong alliances, we’re designing the future. We’ve completed 20 years, but for us, the real journey is just beginning.